Triturex

Triturex Devices

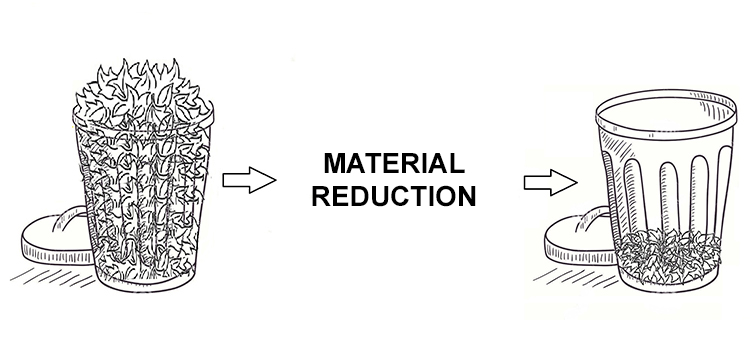

For material volume reduction

Essepi started its business in 1999 and in recent years has supplied sweepers, both road and industrial, to many categories of customers, from industrial sectors to public bodies, with applications in a wide variety of sectors and with different service problems. This has enabled us to increase our knowledge of the various difficulties and methods of solving cleaning problems, understanding the evolution of the need for cleanliness, which in its various aspects aims to be increasingly a quality sweeping service.

Over the years, we have found that many customers need sweepers capable of holding even large volumes of material that quickly fill the container, especially during leaf collection seasons, forcing the operator to waste considerable amounts of time (resulting in a lack of street cleaning), due to continuous transfers to authorised sites to unload the collected material.

With this in mind, our company researched, built and patented a technology called TritureX, producing two devices, which can also be installed individually in sweepers and which allow a reduction in the volume of bulky material collected from around 5 cubic metres to 1 cubic metre.

Patented Triturex

Material shredding

The Triturex® volume reduction device for shredding materials is used at the same time as the sweeper is working and is installed inside the waste container.

The device is operated for the work/rest/wash phases by the operator from the driver's seat.

Furthermore, the special installation position of the device inside the container allows it to remain installed throughout the year without having to be uninstalled.

Triturex

Material shredding

The TritureX volume reduction device for shredding materials is used when using the rear debris suction tube. The device is installed outside the waste container, at the inlet of the material collected by the debris suction pipe, so that all material collected by the machine passes through and is consequently shredded by the TritureX device.

The device is operated for the work/rest phases by the operator from a special button on the device itself.

Furthermore, the special installation position of the device outside the container enables it to remain installed throughout the year without having to be uninstalled.